Description

Product details

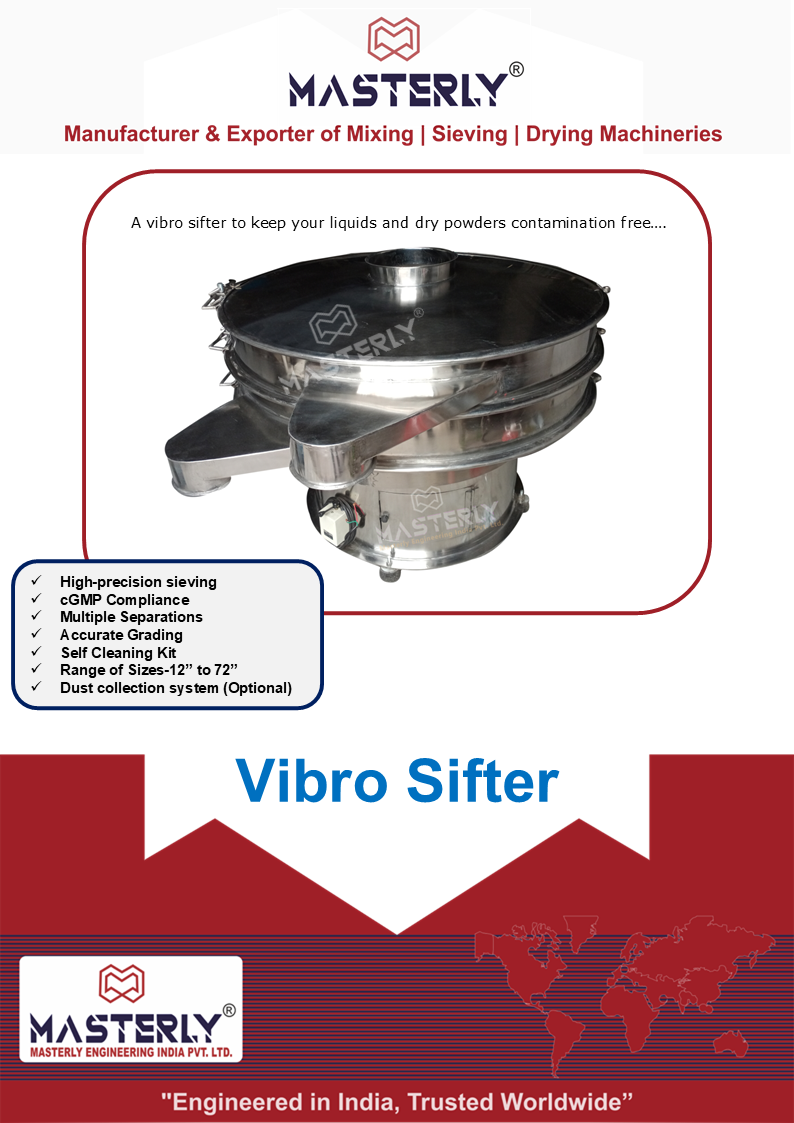

The Masterly Compact range of Vibro sifters A vibrating sifter to keep your liquids and dry powders contamination free Vibro sifters, also known as safety screeners, vibrating shifters, vibro sieves, check screeners or control sieves, are used to ensure the correct product quality of powders or liquids is achieved by removing oversize contamination. The Masterly Compact range of sifters are incredibly versatile and can be used for size based separation of almost any material. These vibrating sifters fit neatly into production lines, providing considerable screening capacity without requiring excessive headroom. Its innovative design means these machines are less than half the height of a traditional circular vibro sifter machine. How Does a Vibro Sifter Work? Vibro Sifter are driven by vertically mounted vibratory motor having eccentric weight at the top & bottom end of the shaft. At the time of Motor rotation top weight causes vibration in Horizontal plane whereas the rotation of bottom weight causes tilt & vibrations in vertical plane. By changing their lead angle, the motor generates vibrations that move the material across the screen. Finer particles pass through the mesh while larger ones remain on top. various spiral-screening patterns are obtained to suit different application. “Masterly” vibro screen provides optimum screening & assures maximum feed-rate & efficiency. Vibro screen is also known vibrating screen, vibro sifter, vibro grader, rotary screen, etc... Depending on the application, a vibro sifter manufacturer can customize the number of screens/Decks and mesh sizes to meet specific requirements. Features & Benefits of Using a Vibro Sifter High Efficiency: Ensures faster throughput and consistent quality. Versatility: Suitable for wet and dry sieving. Easy Maintenance: Tool-free screen change and easy cleaning. Compact Design: Saves space in production areas. Dust-Free Operation: Promotes hygiene and worker safety, crucial in pharmaceutical and food sectors. Multiple Separations: - The vibratory separator can be stacked with up to 7 screening decks, separating into as many as five fractions. Accurate Grading: - Thorough and accurate grading are achieved by controlling product screening time, allowing for complete separation. Reduced Downtime: - The simple and robust design will continue to function with very little mechanical intervention. Range of Sizes: - The separators are available in 12” 18” 24”, 30”,36”, 48”, 60” and 72” diameters to handle throughputs ranging from a few kilograms to a few tones. Dust Cover: - It is composed of a feed inlet and an oblique cone, and its lower end is connected with the screen frame to prevent the dust in the workshop from falling into the material when the vibro sifter is working. The commonly used materials are stainless steel SS304 or SS316 & Mild Steel. Advantages of Vibro Sifter • Compact and portable design. • Guarantee low noise operation and high-speed operation. • Energy efficient equipment • Uses a optional flame proof motor material. • Made from high grade stainless steel 304, 316. • Better dust handling capability. • Many screen options such as double or triple. • Easy to dismantle and clean. • Adjustable vibratory motion. • Sturdy and robust design. • Easy to install and operate. • Design should allow for easy and fast changing of sieves. • Guarantee high performance. • Durable to guarantee a long service lifespan thereby reducing maintenance costs. • Easy Maintenance Save on maintenance with a piece of equipment engineering to last. Toggle clamps allow fast dis-assembly for regular cleaning. Screen Type: Screen Frame: - Sandwich Screen Ring Comes with Bolting Systems Which will enable the mesh frame to change mesh Cloth In-House. Silicon Moulded Screen – Silicone-moulded screens are suitable for pharmaceutical applications, where contamination control is crucial, also used in Food or chemical Industry. Mesh cleaning device: - (Screen De-Blinding Kit Mesh Deblinding Kit is an Anti-Blinding Device which contains Food Grade ball with the help of the vibration the ball start bouncing and prevent the mesh blinding. An anti-blinding Ball Tray Arrangement, comprising of a coarse mesh beneath the sizing mesh on which a sufficient number of elastomer or polymer balls are placed to continuously tap the sizing screen to remove dry particles of the material which is screened and increase screening efficiency. Optional Attachment: Attachments for Vibro Sifters can enhance their functionality and efficiency. Some common attachments include: Attachments Screw Conveyor: Screw conveyors can transport materials to or from the Vibro Sifter. Masterly Screw Conveyer can feed materials into the Vibro Sifter at a controlled rate. They can control the flow of materials into or out of the Vibro Sifter. By combining a screw conveyor with a Vibro Sifter, you can create an efficient and automated material handling system. Feeding Hopper: The feeding hopper stores materials before they are fed into the Vibro Sifter. It provides a controlled flow of materials into the Vibro Sifter, A well-designed feeding hopper ensures efficient material handling and reduces downtime, By providing a controlled flow of materials, the feeding hopper can improve the Vibro Sifter's screening efficiency. Features option for Hopper: Level Sensors, Vibratory or Agitation Systems, Ultrasonic Units: These units use high-frequency vibrations to improve screening efficiency and reduce blinding. Brushes or Cleaning Systems: These attachments help clean the screen and prevent clogging. Vibration Intensifiers: These attachments amplify the vibration intensity, improving screening efficiency. Screen Guards: These attachments protect the screen from damage and wear. Collection Chutes: These attachments facilitate the collection of screened materials. Benefits 1. Improved Screening Efficiency: Attachments can enhance screening efficiency and reduce downtime. 2. Increased Productivity: By optimizing the screening process, attachments can increase productivity. 3. Reduced Maintenance: Some attachments, like cleaning systems, can reduce maintenance needs. 4. Enhanced Product Quality: Attachments can help ensure high-quality separation of particles. Customization Attachments can be customized to fit specific Vibro Sifter models and applications. It's essential to consult with the manufacturer of vibro sifter or supplier to determine the most suitable attachments for your needs. Range of Models: - Applications Across Industries: Pharmaceutical Sifter Ensures tablet and capsule powders are free from contaminants and uniform in size. Food & Beverage Used for sieving spices, flour, sugar, and other dry powders or liquids. Chemical Industry Separates active ingredients and intermediates with precision and prevents cross-contamination. use pictures in slides of industry we serve Choosing the Right Vibro Sifter When selecting an industrial sieving machine, consider the following factors: • Material of Construction: Stainless steel (SS 316 or SS 304) is ideal for hygiene-sensitive industries. • Capacity Requirements: Choose based on batch size and production rate. • Number of Layers: More layers mean more separation precision. • Vibration Mechanism: Ensure it’s suited for your material’s flow characteristics. Always opt for a trusted vibro sifter manufacturer that offers technical support, customization, and after-sales service. Final Thoughts The Masterly vibro sifter is more than just a sieving tool—it’s a quality control asset. Investing in the right vibro sifter machine enhances product quality, streamlines production, and ensures compliance with industry standards. Looking for the best solution? Choose Masterly Engineering as your reliable vibro sifter manufacturer who understands your industry’s needs and offers high-performance sieving solutions. MASTERLY VIBRO SIFTER’S VIDEOS • RELATED PRODUCTS ALL PRODUCT FROM SIEVING CATGORY HERE IN SLIDE