Description

Product details

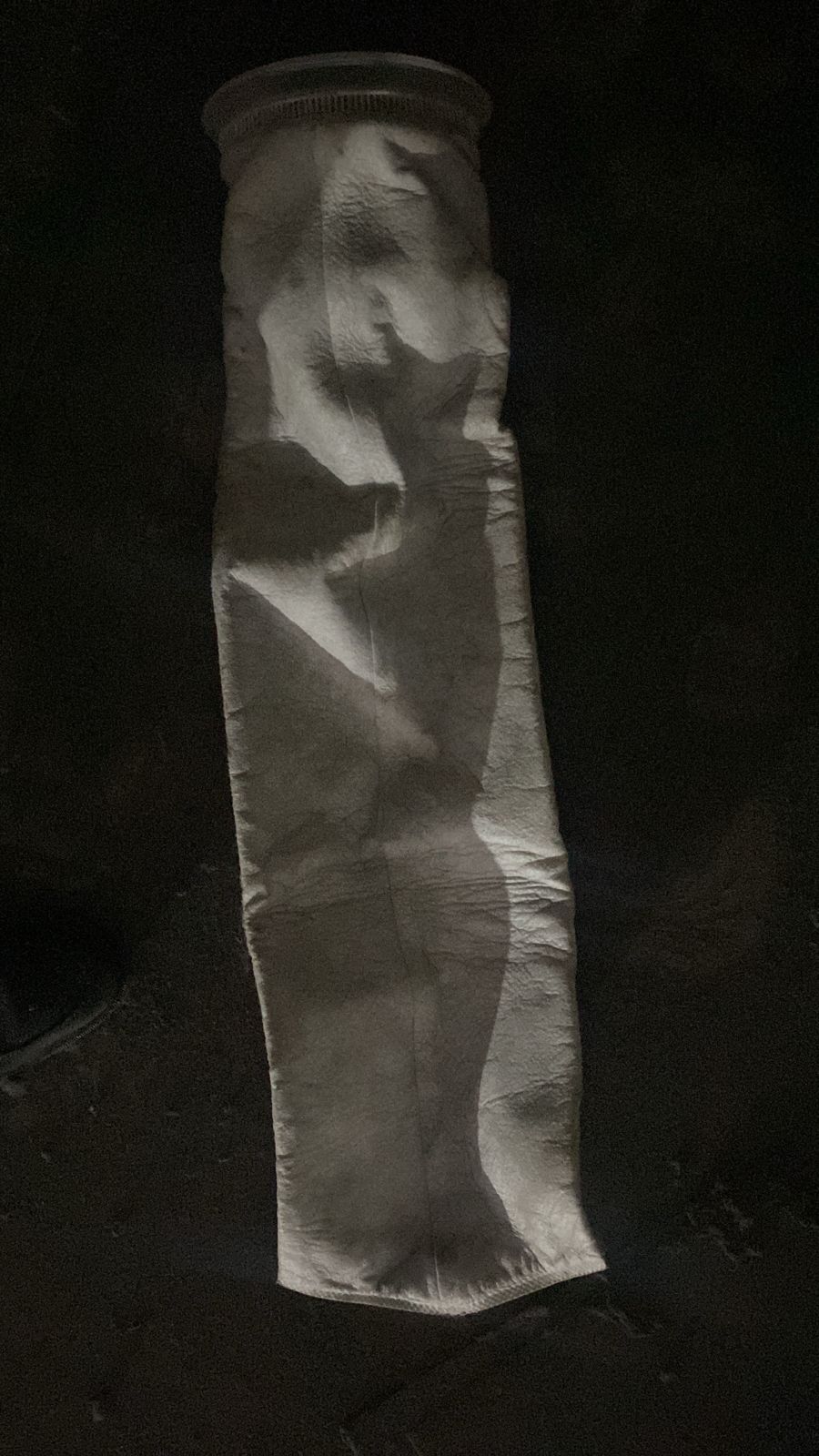

A cartridge filter is a type of filter used to remove particulates, contaminants, or impurities from liquids or gases by trapping them within a replaceable cylindrical element (the cartridge) housed in a filtration system. These filters are widely used across various industries due to their efficiency, ease of replacement, and versatility. 🔧 Basic Structure A cartridge filter typically consists of: Filter media: The material that captures impurities (e.g., polypropylene, cellulose, activated carbon, stainless steel). Core: Provides structural integrity (often made of plastic or metal). End caps: Seal the cartridge to the housing. Outer cage or netting (optional): Adds durability. Types of Cartridge Filters Depth Filters Particles are trapped throughout the thickness of the media. Good for capturing a wide range of particle sizes. Example: Melt-blown polypropylene filters. Surface Filters Particles are trapped on the outer surface. Suitable for applications requiring precise filtration. Example: Pleated filters. Pleated Filters Increased surface area due to folds. Higher dirt-holding capacity and longer life. Carbon Filters Contain activated carbon. Effective for removing chlorine, taste, odor, and organic compounds. Membrane Filters Designed for microfiltration, ultrafiltration, or nanofiltration. Used in sterile filtration and high-purity applications. 📐 Specifications Micron rating: Defines the particle size the filter can remove (e.g., 0.2 µm, 5 µm, 50 µm). Length and diameter: Common sizes are 10“, 20”, 30“, and 40” in length. Material compatibility: Chosen based on the fluid being filtered. Flow rate capacity: Depends on design and application. 🏭 Applications Drinking water purification Pharmaceutical and biotech processing Food and beverage production Oil and gas Paints and coatings Chemical processing Semiconductor manufacturing ✅ Advantages High filtration efficiency Easy to install and replace Compact and space-saving Customizable for different filtration needs Available in sterile/cleanroom-compatible versions ✅ Reasons to Install a Candle Filter: 1. High Filtration Efficiency Candle filters are designed to remove very fine particles (often below 1 micron). Ideal for polishing applications where ultra-clear filtrate is needed. 2. Closed-System Operation Operates under pressure in a sealed housing, minimizing exposure to air and contaminants. Suitable for hazardous, toxic, or flammable materials. 3. Backwash/Regeneration Capabilities Candles can often be cleaned and reused using backflushing, reducing operational cost and downtime. 4. Minimal Product Loss Solids are retained on the outer surface or within the porous candle, allowing for efficient recovery of valuable products. 5. Automation-Friendly Many candle filter systems are designed for fully automatic operation, including cake drying and discharge. Ideal for large-scale, continuous processes. 6. Space-Saving Design Vertical design with multiple candle elements allows for a high surface area in a compact footprint. 🏭 Typical Applications Pharmaceuticals: Clarification of APIs, sterile filtration Chemicals: Catalyst recovery, polymer solutions Food & Beverage: Wine and juice clarification, edible oil polishing Fine Chemicals: Resin filtration, pigment separation Metallurgy: Electrolyte purification ⚙️ How It Works (Simplified): Liquid enters the vessel and flows through the porous candle elements. Solids are captured on the surface of the candles (forming a cake). Clean liquid exits through the center of the candles. When the cake builds up to a certain level, it can be backflushed or removed by blowdown. If your process requires high-purity output, low contamination risk, and efficient solid separation, a candle filter is often the best choice.